P1 Group Exceeds National Averages Through Staunch Commitment to Safety

Making sure conditions are safe for the 900+ people working at P1 Group jobsites on any given day is a huge task, but in a company where safety is the highest priority, no one takes shortcuts.

Like any organization of this type, P1 Group is required by the Occupational Safety and Health Administration (OSHA) to keep records of the number of recordable incidents, which include the number of injuries on the job and the number of lost or restricted workdays from injuries.

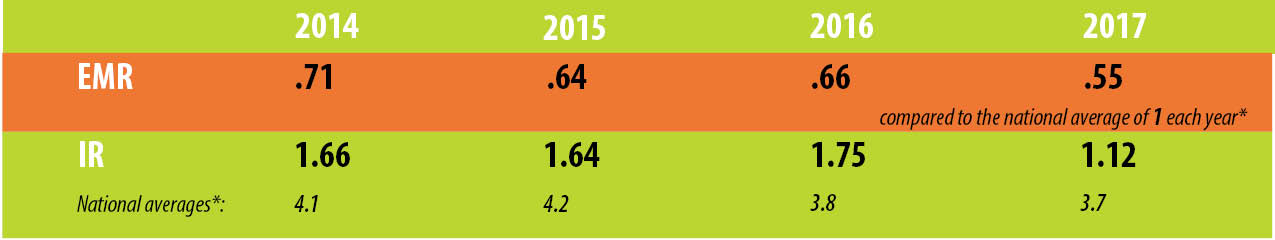

Thanks to our Safety Team, who are always pursuing innovative ways to put safety first, P1 Group has successfully kept our “recordables” low, putting our Experience Modification Rate (EMR) and Incident Rate (IR) above national averages.

Don Campbell, Vice President, said the ultimate goal is no injuries at all. But there are other reasons to keep our EMR and IR low. “Safety affects our ability to get the big projects and keep everyone working – at the jobsites and in our offices,” Campbell said.

Cut-resistant gloves are an example of a newer safety requirement that has had a noticeable impact on P1’s Safety stats. A more serious hand laceration can cut into a tendon, requiring surgery and lost or restricted workdays. Making sure associates have the best equipment can ensure this doesn’t happen.

The table below shows P1 Group EMR and IR since 2014. The lower numbers indicate not only improvement over time, but the fact that P1 Group is exceeding the national average.

Communication is key, and the Safety Department diligently communicates regularly with associates and their families to keep safety top-of-mind.

“Safety First…Quality Always.” That’s the P1 Group Safety motto, and we live it every day.

*According to the Bureau of Labor Statistics

About the author

P1 Construction is a single-source specialty subcontractor specializing in mechanical, electrical, millwright, and architectural metal construction facility solutions.