Profile: Wolf Creek ESW/CAC Replacement Project

When the Wolf Creek Nuclear Operating Corporation requested a proposal for the Essential Service Water and Containment Area Cooler Replacement Project scheduled for Refuel 22, P1 Group was the natural choice.

According to Tom Crumrine, nuclear division vice president, the project was competitively bid out to four or five contractors. P1 Group was awarded two large portions of the project based on past performance and long-standing relationship with Wolf Creek.

“Due to our knowledge and understanding of the client, P1 Group structured a bid that specifically targeted their needs, and Wolf Creek determined P1 was the best fit,” Crumrine said.

Wolf Creek Nuclear Operating Corporation operates the Wolf Creek Generating Station, Kansas’ first, and only, nuclear power generating station for several utility owners in Kansas and Missouri.

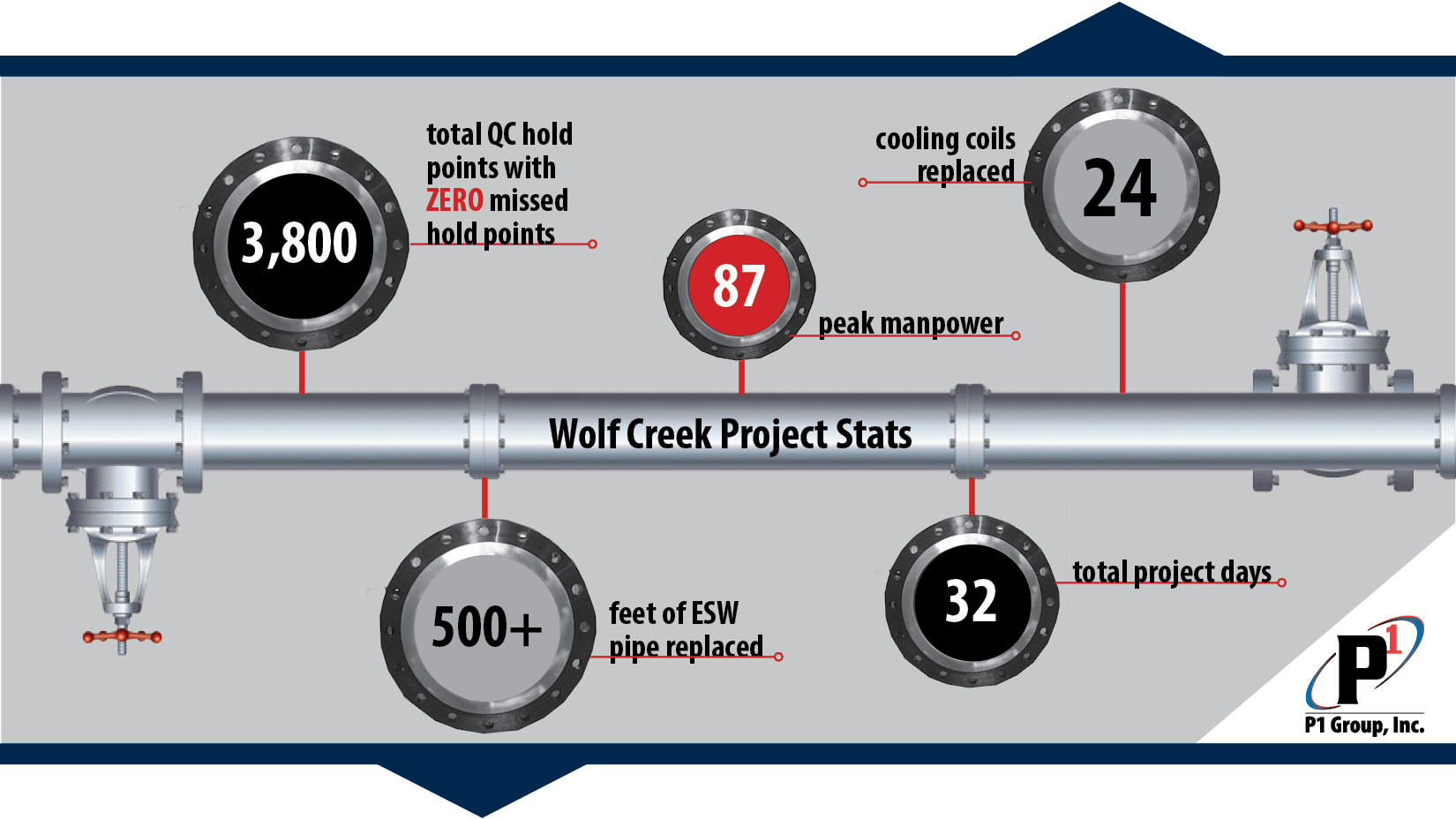

The two-fold scope of this project included replacement of twelve cooling coils and eight associated manifold header pipes on the CAC units. Additionally, P1 Group was selected for the prefabrication of piping assemblies prior to the refuel and the replacement of approximately 540 feet of ESW pipe.

Here’s what P1 Group did:

- Replaced a total of 24 coils (12 per unit) in two of four units in the Containment Building. These cooling units are designed to maintain optimum ambient air temperatures in the Containment Building during online operations of the plant. Replacement involved removal of the existing coils, installation of new coils, fabrication of new manifold headers built pre-outage and welding them in place.

- Prefabbed portions of the above for a mockup demonstration in the New Strawn fab shop.

- Replaced more than 500 feet of above ground ESW piping in the Radiologically Controlled Area (RCA).

- Prefabbed portions of the above in both the Lawrence and New Strawn fab shops for a mockup that included strut hangers, box hangers, pedestal hangers, replacement modification, removing old pipe and installing new pipe ranging from two inches-30 inches.

- Using all its own trucking, P1 transported material from the client’s warehouse to New Strawn and back. In fact, P1 moved all its own equipment and did all its own material handling.

Crumrine also noted this was a project with higher risk than past projects at Wolf Creek since it took place on the “hot side” of the plant (auxiliary and containment buildings). P1 Group workers had to be dressed properly, were limited in their stay times and required close monitoring at all times.

Past P1 Group projects with Wolf Creek include maintenance weld shop augmentation for five consecutive refuels, ESW pumphouse and circulating water pumphouse work, FAC piping replacement work, ESW underground support, ESW above-ground replacements and the water hammer modification.

100 Years Strong: Over the last century, P1 Group has built strong relationships and solidified customer trust with clients like the Wolf Creek Nuclear Operating Corporation. We are proud to continue serving long-time clients and look forward to developing solutions for new ones in the years to come.

About the author

P1 Construction is a single-source specialty subcontractor specializing in mechanical, electrical, millwright, and architectural metal construction facility solutions.